|

| UNISPEC FRANCHISE PROGRAMME |

INDUSTRIAL PRODUCTS FRANCHISING is a

modern system of international marketing. It permits the introduction

of products of common identity, design, use and name to every part

of the world without having to re-invent the wheel, so to speak.

It is an intelligent way to overcome the common problems of distribution,

as it ...

a. Eliminates the need to hold large stocks.

b. Eliminates out-of-stock positions.

c. Adds ability to fill large customer orders without back orders.

d. Eliminates the need for expensive rush shipments.

e. Eliminates expensive sea shipments due to IMO regulations for

chemical products.

f. Avoids cost increases due to high handling costs of frequent

orders.

g. Eliminates the high cost of financing large stocks of finished

products.

| THE UNISPEC FRANCHISE - SPECIFIC BENEFITS: |

Unispec's Franchise Programme eliminates all expensive and unnecessary

distribution activities. It offers the following tangible and customer

appreciated benefits:

| |

i. |

Allows a distributor to produce

any item on the Unispec Product List, in any quantity, thus

always satisfying customers' orders, regardless of size, when

simple importers fail because of small stocks, stock-outs or

delayed delivery of goods from their suppliers. |

| |

ii. |

Allows a distributor, through

local production, to reduce prices much below competitions by

eliminating the finance cost of imports, transport and customs

clearing costs for odd lots of goods and the extra cost of shipping

dangerous goods by IMO standards for the chemicals and sprays. |

| |

iii. |

Allows a distributor, through

his own production and with the support of the Unispec chemists,

to manufacture "own label" goods for other companies

so adding to his volume and solidifying his position in his

market. |

| |

iv. |

Allows a distributor through

the back-up of Unispec's chemists to stay ahead of EC and International

regulations relating to Safety and proper uses of products.

|

| |

v. |

Allows a distributor to get into the AEROSOLS (SPRAYS) market and to fill spray cans for others in their name.

|

Most important is that the UNISPEC FRANCHISE PROGRAMME makes it possible

for a distributor to always be in position to fill orders ON SHORT

NOTICE and to NEVER RUN OUT OF STOCK. To never be out of stock is

considered by many people as a "pie in the sky", a dream so to speak,

but a dream very possible to realize under the UNISPEC FRANCHISE PROGRAMME.

| WHAT IS THE UNISPEC FRANCHISE

PROGRAMME |

The Unispec Franchising Programme is a scientifically planned and

Company guided transfer of Capability to Blend Chemicals from Unispec

to a Unispec distributor come partner. It allows a distributor to

progress from simple 'importing and distributing' to 'manufacturing

and distributing'. Authorized Goods of Unispec owned designs and formulations

are blended in a plant built "turn-key" by Unispec for a

distributor in his own country.

The Franchise Programme allows the spreading of the costs of research,

design, legal protection, advertising and production across a larger

area of the world resulting in standardized products of proven quality

bearing a top name like UNISPEC and being available to all people

internationally at reduced prices.

And, lastly, it allows for businessmen to enter into new areas

of activity, like manufacturing, at literally no risk.

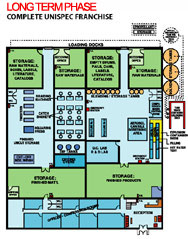

A full blown manufacturing facility of Maintenance Chemicals, Aerosols

and Liquid Sealing Products is shown in the enclosed UNISPEC ENGINEERING

DRAWING No. 80,000. It is the end picture of the long term evolution

from plain distributorship to a production, storage and distribution

set up. It also shows the specialized machinery to be made available

to a distributor who decides to become a Unispec Franchisee.

The Unispec Franchise programme is divided into two phases;

| i. |

SHORT TERM

PHASE: For blending and packaging Unispec Brand BULK-PACKED

maintenance chemicals and Unispec aerosol sprays (optional).

(Diagram 80004) |

ii . |

LONG TERM

PHASE: A fully expanded manufacturing plant that includes

Aerosol Sprays and Mechanical Packings, as shown in the UNISPEC

ENGINEERING DRAWING No. 80000, and into which a distributor

can gradually grow by mutual agreement with Unispec Corporation.

|

| SHORT TERM PHASE 1 (DRAWING

No. 80004): |

(Diagram 80004)

click image

to enlarge

|

|

For blending and packaging Unispec

Brand BULK-PACKED maintenance chemicals and Unispec aerosol

sprays. A physical view of the short term Franchising Programme

is shown in approximate terms on the attached Unispec Corporation

Plant Drawing No. 80004 and it is designed to introduce the

manufacturing of the fast selling and large volume Unispec maintenance

chemicals in any market and in any country where there are visiting

ships and where there is industry.

The reasons for expanding plain distribution into manufacturing

were expanded above. This phase follows a period of imports

of finished products directly from Unispec by the distributor

to provide for the necessary market penetration and sales volume

which the plant is expected to satisfy. |

| LONG TERM PHASE 2 (DRAWING

No. 80000): |

(Diagram 80000)

click image

to enlarge

|

|

A physical view of the long term

Franchising Programme is shown in approximate terms on the attached

Unispec Corporation Plant Drawing No. 80000 and allows for the

setting up of a complete manufacturing operation for the following:

| |

1. |

Unispec Bulk-packed chemicals

in drums and in cans. |

| |

3 |

Unispec Mechanical Packings

and glass fibre packings. |

| |

4. |

Glass & Ceramic Fibre

twisted ropes, cloth, etc (machinery not shown). |

|

| ANALYSIS OF PHASE ONE, UNISPEC/DISTRIBUTOR INPUT: |

A. UNISPEC INPUT FOR PHASE ONE:

1. UNISPEC will ship and install at its own cost one complete basic

plant comprised of:

| |

i. |

10 x 1000 litre, chemically resistant,

holding tanks complete with one gravity fed unloading valve

attached to each. |

| |

ii. |

Two x 2500 litre tanks. One as holding

tank for finished products. The other as holding tank for water.

|

| |

iii. |

One, two-motor 500 - 1000 litre

high capacity air compressor complete with air dehydrator and

lubricator. |

| |

iv. |

One air operated pump with PTFE

diaphragm or electrical pump of equivalent capacity, at Unispec's

option. |

| |

v. |

One "petrol pump" type

nozzle with flexible hose as outlet from main pump. |

| |

vi. |

Five hand operated drum pumps. |

| |

vii. |

One 50 kilogramme powder mixer. |

| |

viii. |

One electronic weighing scale to

about 200 kilogramme capacity. |

| |

ix. |

One mechanical weighing scale to

about 300 kilogramme capacity. |

| |

x. |

Quality Control Testing Equipment: pH meter, Lab Glassware, Pipettes, Scale, Viscosity Meter. |

2. UNISPEC will ship at no charge the following concentrates for the

start-up under the Franchise Agreement:

Each concentrate gives its final mother product, as for example the

AIR COOLER CLEANER or the TANK & BILGE CLEANER, their personality

and key signature. Each concentrate will give the mother product its

representative pH, its inhibitive action on metals, viscosity, speed

of penetration, surface activity, colour, smell, flammability level,

safety level and International or EC demanded safety codes.

It must be expressly accepted and understood by all parties that

Unispec will always be the sole and only source of supply of concentrates,

for any and all Franchise Programmes in any country. Concentrates

are the formula inputs that tie up a finished product to it's registered

name, the formula owners, its quality, price, conformity to international

standards and safety.

Only the standard high volume chemicals as specified by Unispec,

some of which are listed below, can be bought from outside sources

by Franchisees following written acceptance of source, quality and

price.

The philosophy here is to use "IMPORTED CONCENTRATES FROM

UNISPEC and LOCALLY BOUGHT SECONDARIES".

The list below represents the bulk of the chemical concentrates

required to operate a new blending facility to a "full stock

position". Other products may be added at a later date to provide

for product range expansion.

| UNISPEC SUPPLIED CHEMICAL CONCENTRATES: |

A. CLEANERS' CONCENTRATES:

| |

ii. |

Carbon & Varnish Remover. |

| |

iv. |

Coil & Metal Bright, Acidic/Alkaline. |

| |

vii. |

DeLaval Disc Cleaner. |

| |

viii. |

Descaling Liquid & Powders. |

| |

ix. |

Electrical Equipment Cleaners. |

| |

x. |

Emulsion Solvent (Grease and

Oil Remover), Ecological/Standard. |

| |

xii. |

Heavy Duty Alkaline Cleaner. |

| |

xiv. |

Metal Cutting Coolant, Emulsifiable. |

| |

xvi. |

Sheet Metal Deruster &

Phosphate Agent |

| |

xvii. |

Tank & Bilge Cleaner, Standard. |

| |

xviii. |

Tank & Bilge Cleaner,

Eco. |

| |

xx. |

Others as may become necessary

in time ... |

B. WATER TREATMENT CONCENTRATES:

| |

a. |

Boiler Water Concentrates. |

| |

b. |

Evaporator Water Concentrates. |

| |

c. |

Cooling Water Concentrates. |

| |

d. |

Diesel Engine Water Treat Concentrates. |

C. FUEL TREATMENT CONCENTRATES:

| |

1. |

Fuel Oil Catalyst Concentrate. |

| |

2. |

Fuel Oil Sludge Conditioner Concentrate. |

D. SURFACE PROTECTION CONCENTRATES:

| |

A. |

Rust Guard, Heavy Duty Protective

Wax. |

PACKAGING MATERIALS:

One 20 foot container-full of 20 litre and 30 litre Heavy Density

Polyethylene cans to Unispec specifications, colour and embossed branding

with Unispec's logo.

LABELS:

An appropriate number of labels for an approximate three month period

of production. Screen Printed Labels for relatively small production

runs is very expensive. Unispec intends to supply them as "house

policy" to ensure global uniformity.

DRUM SEALS:

Drum seals, either plain or with Unispec Logo, will be supplied together

with the appropriate sealing tool.

UNISPEC MANPOWER:

One Unispec Chemical Engineer or Unispec Production Engineer/Manager,

for approximately a two week period, will attend and supervise the

installation of the equipment and train the production people appointed

by the distributor.

The above represent a complete package of the required equipment,

quality control material, concentrates, packaging material, labels,

seals, supplies and manpower to set up and operate a blending facility

for Unispec type maintenance chemicals. They will be supplied NO-CHARGE

by Unispec and will be put in place at a distributor provided location

as part of the Franchise Agreement.

| B. DISTRIBUTOR INPUT FOR PHASE

ONE: |

PHYSICAL BUILDING FOR THE BLENDING PLANT:

The distributor must provide the basic building and facilities in

which to house the blending operation. The approximate physical space

requirements are shown in Drawing No. 80004 and are about 400 square

meters of covered ground level space with ample lighting and adequate

windows to achieve good air flow.

The building shall have at least one large sliding door able to

accommodate the entry of one 40'container carrying platform, at

least two safety exit doors and at least 10 large windows to allow

for ample natural lighting and to allow for good air flow.

There should also be a separate 400 square meters of an uncovered

or shaded belt of free land around the building. The uncovered space

will be used to store packaging material like drums and 20/30 litre

drums preferably inside a used 40 foot container or under a shaded

area.

All electrical connections must be in place for a three phase electrical

supply and an adequate number of electrical outlets protected by

a cover.

All plumbing facilities including two W.C., and showers.

The distributor should also arrange for the purchase or rental of

two pallet carriers of 2 tonne capacity and one LPG or electric

fork lift truck, with soft tires, 3 tonne lifting capacity and a

telescoping boom enabling it to operate inside a container.

THE ENVIRONMENT & OPERATING LICENSES:

The production process of these Unispec products has no polluting

effect on the environment. There are no contaminating by-products

generated from the mixing of the various chemicals and there are

no chemical reactions forming by the blending process. In addition

there are no leaks from the process as all tanks and equipment are

leak tight and air operated.

In case of accidental spills the lost quantities are small and

are easily contained within the building to be picked up at a later

time and forwarded to a licensed spill contractor.

Operating licenses should be granted, in any country, without any

problem.

SECONDARIES TO BE PURCHASED LOCALLY BY DISTRIBUTOR:

The secondary chemical products that follow must be supplied by

the Franchisee. They will be bought in volume and will be used to

produce the various Unispec products. They constitute a large percentage

of the bulk raw material of the local production and it is their

local availability and low prices which will make the whole Franchising

Programme feasible and financially interesting. Price per kilo,

packaging and availability of the following in the country of the

Unispec Franchisee must be analyzed to establish project feasibility.

| |

a. |

Base Oil No. 30 (Reprocessed oils

will do). |

| |

c. |

Caustic Soda, Wet (50% concentration). |

| |

g. |

Hydrochloric Acid (30 - 33% concentration

or whatever locally available). |

| |

j. |

Miscellaneous tertiary raw material. |

| |

l. |

Phosphoric Acid (85% concentration

or whatever locally available). |

| |

q. |

Sulfamic Acid (99% concentration

or whatever locally available). |

| |

r. |

Sulfonic Acid (98% concentration

or whatever locally available). |

| |

u. |

Water, city tap water. |

NOTE: The list of Concentrates and Secondaries as shown above

is an indicative list and does not exactly represent the final list

which may be reduced or increased at any time.

PHASE TWO

UNISPEC AND DISTRIBUTOR INPUT |

Phase two is subject to a joint Unispec and Distributor decision to

expand manufacturing to its full potential.

The joint decision is based on the experiences of the parties during

a minimum of one year of production and distribution under the Unispec

Franchise Programme. Potential overall business available in the

distributor's operating area, the quality of the human relationships

developed between Franchisor and Franchisee during phase one and

the financing possibilities all have a bearing on the final decision.

The products that will be made from this phase onward must be able

to compete on price and on quality. Under the Unispec Franchise

Programme prices will be kept very competitive and quality under

control.

We look forward to reaching phase II together with you.

|